Image: GPS.gov

As we close the book on 2019 and head into the next decade, much has changed during the 2010s and the 21st century. This article will focus on the technological changes that made a significant impact on the surveying world, with the biggest advances being specifically GNSS-based improvements.

No, we will not debate the true beginning of a century (Jan. 1, 2000, versus Jan. 1, 2001), but instead look at the predicted issues with computers and the Y2K hysteria leading up to the end of 1999 as part of our nostalgic tour.

For the millennials and Gen-Z readers, bear with us old-timers for a few paragraphs while we take a trip down memory lane.

The tale of two centuries…

“It was the best of times, it was the worst of times, it was the age of wisdom, it was the age of foolishness, it was the epoch of belief, it was the epoch of incredulity, it was the season of Light, it was the season of Darkness, it was the spring of hope, it was the winter of despair, we had everything before us, we had nothing before us, we were all going direct to Heaven, we were all going direct the other way — in short, the period was so far like the present period, that some of its noisiest authorities insisted on its being received, for good or for evil, in the superlative degree of comparison only.”

In 1859, Charles Dickens wrote this opening paragraph for his well-known novel, “Tale of Two Cities,” to describe two environments (in this case being London versus Paris) at a significant transitional time. Such was the case for surveying and technology in the late 1990s with the rapid utilization of GNSS technology, expanded capability of robotic equipment and data collection. Some practitioners were excited about the new century while others yearned for bygone eras of less complicated procedures.

“Gonna party like it’s 1999…”

A 1999 Gateway PC refurbished by LRG. (Screenshot: LRG video, click to view)

With apologies to the late singer Prince and his 1982 hit song, the news surrounding the year 2000 was bleak when it came to computers and technology. For many of our readers, the technology available in 1999 might seem like the Stone Age. Most homes still used telephone land lines, “state of the art” cellphones were being produced by Nokia, personal computers (manufactured by Dell, Gateway, HP and IBM) were utilizing Pentium III processors (at a whopping 450 MHz!) with 5-10 GB storage. Internet Explorer was the web browser of choice, and Napster was gaining users exponentially sharing music downloads. Google was only one year old but rapidly replacing AltaVista and WebCrawler for our internet search engines. Life seemed good, but a storm was brewing…

The Y2K bug was front and center in all media outlets as many computerized systems were not programmed with the year 2000 in mind. This issue was unique in that it was a software and hardware problem to address. Replacement or patching of software, while taking a significant amount of time and money, can be much easier than computers and hardware loaded with chipsets that cannot be reprogrammed.

The Napster logo

Most system programming utilized a two-digit year designation instead of a four-digit version (99 versus 1999) and thus a date entry for January 1, 2000, normally composed as 1/1/00 in older systems would be recognized as January 1, 1900, instead. Because of this situation, many experts were predicting a global meltdown with government, utility company and banking disruptions that would render most computer systems unusable.

In the United States alone, over $100 billion was spent on computer upgrades and troubleshooting of the potential crisis. Thankfully, most of these systems had already been taken offline and replaced, but a few still lingered in critical systems. Because of pre-Y2K upgrade planning, many systems were tested and proven to be immune from the potential crash.

Specific Y2K issues that took place within the U.S. satellite system were isolated mostly to the units dedicated to surveillance, and not the navigation section used by surveyors. There was a small issue with the U.S. Naval Observatory, in which the date was deemed to be “Jan. 1, 19100” but that was rectified quickly.

The U.S. spy satellites, however, were knocked out by a faulty software patch rather than the original programming. These units were producing unusable information for three days before programmers were able to fix the problem. Imagine if that situation had happened to the navigational satellites and was impacting surveyors; we can only hope the GNSS system would have simply provided obvious bogus information.

Embracing RTK

By 1999, surveying had begun to embrace RTK systems for everyday measurement needs. Because of the constant focus of GPS technology moving forward, the operating systems for RTK were ahead of the curve for the Y2K issue. Fortunately, the navigational satellites as mentioned above did not fail with the date and time issues that were being predicted.

Logo of the now-defunct U.S. government Y2K website.

The Y2K bug did, however, affect a few users of older technology and software. Older data collectors, including ones based upon handheld calculators, were susceptible to date issues. Systems that were designed in the 1970s and ’80s should have been replaced with newer technology before 2000, but old surveyors stick to the adage: “If it isn’t broke, don’t fix it!”

For many, it wasn’t simply an upgrade in technology, but more of a radical change in known processes and procedures. New instruments and data collectors required new computers, which required new software, which required learning a completely new system.

Handheld GPS technology, introduced in the mid-1990s, was beginning to grow as the general public was embracing the new ability to determine geographical positions. While their use is quite simplified by today’s standards, nonetheless these devices captured the tech lover’s need for more accurate location determination.

In the end, Y2K wasn’t nearly the technological apocalypse many educated minds feared. While there were a few isolated incidents worldwide, everyday life went on without much of a blip on the radar. Planes didn’t fall out of the sky; financial systems didn’t come crashing down and life went on. Thankfully, surveyors everywhere went about their business on Monday, Jan. 3, 2000 as if nothing happened.

Then 20 years go by…

The new millennium has brought the surveying community many new exciting technologies and vast enhancements to age-old procedures. Field book notes has been mostly replaced with electronic data collectors, cellphone cameras and point clouds. Data is efficiently transferred between field and office with a remote connection and a blink of an eye. These past 20 years has seen a landslide of technological improvements, yet the future looks incredibly bright with more to come.

With the new year and decade, let’s look at where we are today and what advances we are anticipating:

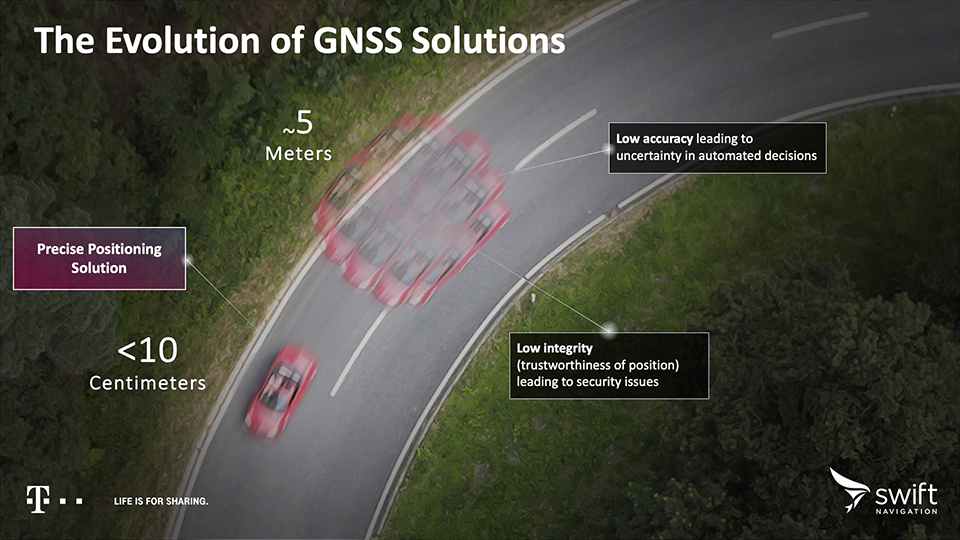

GNSS CAPABILITY

- GPS (Global Positioning System) began working in the U.S. in 1978 and as a true global system in 1994. This system was originally designed to work strictly for the United State military, but was discovered to have consumer applications shortly after implementation. There are currently 30 operational satellites in the GPS constellation with two (2) Block III versions being evaluated at press time. A total of ten (10) Block III satellites are planned to be operational by late 2023 or early 2024. These Block III versions will have an enhanced signal capability (L5 band) and will provide more accuracy and increased protection from jamming and spoofing.

- GLONASS (GLObal NAvigation Satellite System) is the navigation system designed and implemented by Russia. This system was deemed operational in 1993 and currently has 28 operational satellites. Most surveying equipment in the United States has GLONASS tracking capability to greatly increase the accuracy and precision of most GNSS receivers.

China launched two more BeiDou satellites on Aug. 25, 2018. (Photo: CCTV)

- Galileo is the satellite constellation system created by the European Union. It reached limited capability in 2016 with full expanded reach targeted for 2020. However, the reliability of the system is now in question as a total system outage occurred for seven days in July 2019. The satellites themselves were operational; it was the main control center that experienced the shutdown during a system maintenance upgrade. The overall integrity of the system has been restored and the planned rollout of full operational capability is still scheduled for 2020.

- BeiDou, the national navigation system of China, has achieved 35 operational satellites with 13 additional vehicles currently being evaluated for implementation. With the increased number of satellites, many GNSS receiver manufacturers are including BeiDou as standard channel reception to greatly increase accuracy and precision for navigational purposes.

- Two additional regional systems, QZSS (Quasi-Zenith Satellite System) from Japan and IRNSS (Indian Regional Navigation Satellite System) from India are currently working to install more satellites and provide navigation signals soon. Because these are regional systems, access to these signals for U.S.-based surveyors will not be available.

In 20 short years, we went from having two good systems to four very robust systems and two regional organizations.

While it is still unclear how political relationships will affect the ability to use a system from another country, the simple fact is that more vehicles in space will only increase the coverage, reliability and effectiveness of GNSS navigational data. Increased signal type and strength will also provide many benefits, so surveyors should look forward to even better GNSS days ahead.

ADDITIONAL CELLPHONE CAPABILITY

Several increases in cellphone technology will greatly enhance not only the consumer’s use of GNSS but the surveyor’s. This involves a two-step increase in value with the rollout of 5G signal technology and dual-frequency GNSS receiver hardware within the cellphone.

5G is being introduced in various markets around the country, but won’t see full potential until 2021 and beyond. Those who can use it in the short term will see greater bandwidth for data connectivity, but surveyors will start utilizing navigational enhancements because of the signal and transmitter technology.

Broadcom’s latest dual-frequency chip. (Photo: Broadcom)

Add to this mix the future implementation of dual-frequency GNSS chipsets to provide much more accurate location, and the surveyor will have more data-collection power in their pocket. Dual frequency was a gamechanger for GPS receivers in their infancy, so one can only imagine how much it will enhance the navigation accuracy when included in the cellphone.

REAL-TIME NETWORKS (GNSS)

Most urban and suburban surveyors already enjoy the benefit of a real-time network, either from a private or public system. With 5G and expanded use of more satellites and L5 signal, the RTN will become a better tool for surveyors everywhere. A reduction of setting up a base station increased productivity, less theft and less equipment costs. The RTN will become a standard operational tool just like having a total station in your survey rig.

DATA COLLECTORS

Photo: Spectra Geospatial

The technology hasn’t stopped with the unveiling of new data collectors and platforms. Small handheld devices used to rule the field surveyor’s world; now those devices have become bigger and more advanced than ever.

While most collectors already had touchscreens, the actual screen is increasing in size and functionality. Some are adopting the tablet-style format (8- and 10-inch screens), others are incorporating larger screens (7 inches) within the body of the traditional collector. All of them are including better cameras and enhanced connection capability through Wi-Fi, Bluetooth and cellular methods.

Also catching on is the use of bring-your-own-device (BYOD) with specialized apps for connecting to newer GNSS receivers. This allows surveyors to keep down costs of equipment by not having to purchase a dedicated data collector. As mentioned previously, once the cellphone becomes equipped with 5G and/or dual-frequency GNSS, it will become an excellent system for surveying that will produce extraordinary value for the surveyor.

SPATIAL DATA

The biggest revolution for surveyors in the coming years will be the ability to collect spatial data through a variety of equipment and sensors. Besides the obvious explosion of UAV capability, the small-format laser scanner is becoming user- and drafter-friendly as well as much more affordable. Now a surveyor can perform dozens (if not more) of small area scans with simplified orientation and scan formatting to create a great looking point cloud for data extraction and/or Building Information Modeling (BIM). Surveyors are beginning to understand how to utilize this technology and data to reach inaccessible areas and densified regions quickly. In addition to scanning technology, SLAM (simultaneous localization and mapping) will also become more mainstream as more surveyors are adopting the method for data collection.

What we’ve learned

“The days are long, but the years are short.” – Gretchen Rubin, author

Gretchen hit the nail on the head, as these past two decades have rolled on. When the end of 1999 was upon us, it seemed to be a big deal because of the potential of Y2K issues. There we were, surveyors with exciting technology in our hands, and now the forefathers of computers were going to erase it all due to not looking ahead to the next century.

We easily got past it, yet the memories of Y2K still linger on for some of us. The jump to 2010 didn’t foreshadow any drama (other than climbing out of a recession) and I personally didn’t think any different while moving the calendar to January 2020. But somehow in the last few months of 2019, there were many stories about the Y2K predicament, and it rekindled old memories of those weeks leading up to January 1, 2000.

Long story short, we survived and lived to survey many more days. Having time to look back and compare where we were 20 years ago to where we are now, I find it simply amazing. No, Rick Deckard isn’t flying by in his car catching bad guys (Blade Runner was set in 2019!), but surveying continues to amaze me with continued technological changes.

I wonder what the next 20 years will bring.

Gilla detta:

Gilla Laddar in …